- posted on

Limitations of Molded Pulp (What You Need to Know in 2025)

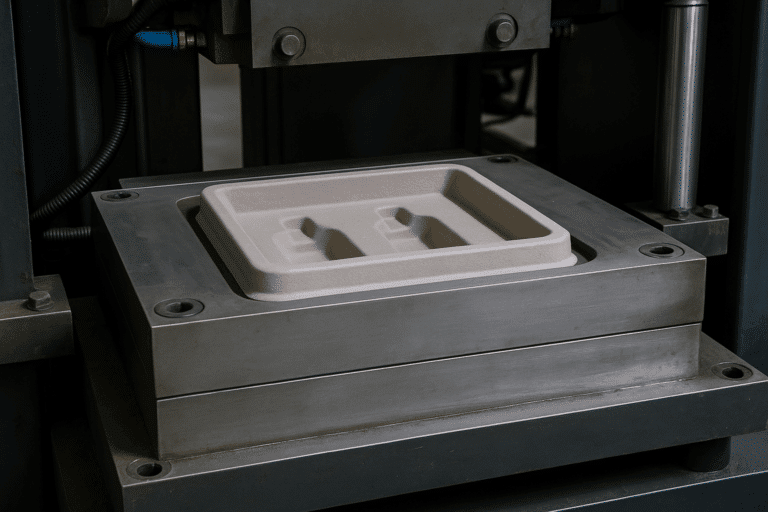

While molded pulp packaging offers a powerful combination of sustainability, protection, and custom design, it isn’t without its trade-offs. In this article, we break down the most common challenges, drawbacks, and limitations brands should be aware of when considering molded pulp for their packaging needs.

Is Molded Pulp Waterproof or Water-Resistant?

Molded pulp in its most basic form is made from a mixture of natural fibres and water, as such it is not waterproof and has very low water-resistance. However, many manufacturers add waterproofing agents to improve the water-resistance.

At Fenix Industries, we use a water-based biodegradable solution called AKD. This solution allows our molded pulp packaging to hold water for up to a week without compromising the sustainability aspect.

For more information regarding waterproofing solutions for molded pulp packaging, please see here.

Can You Customize the Colour of Molded Pulp Packaging?

Yes! You can customize the colour for molded pulp packaging. However, not every factory has the ability to produce custom colour molded pulp due to regulations for waste water treatment.

With Fenix Industries, you can customize your molded pulp packaging to the colour that you need. However, we would kindly suggest against coloured pulp for the highest standard of environmental friendliness.

Bio-based dyes are available as an option but have a tendency to leech from the pulp onto the product, we generally would not recommend this as well.

For more information about custom colour molded pulp, please see here.

Why is Molded Pulp Tooling Expensive?

For brands considering the switch to molded pulp packaging, tooling costs can initially seem daunting, but they’re a strategic investment. Molded pulp production typically requires multiple molds (for forming, pressing, and trimming), which ensures precision and repeatability at scale.

At Fenix Industries, our custom tooling starts around $4,000 USD and is built to last over 500,000 production cycles. Beyond durability, custom tooling offers brands complete creative control, from structural design to branding, while also supporting sustainability and ESG initiatives.

Is Molded Pulp Packaging Slower to Produce?

Molded pulp packaging generally has a longer production cycle compared to traditional materials like plastic or rigid board. This is primarily due to the nature of its forming and drying processes.

Wet Press: In wet press molded pulp, although moisture is removed through heat compression rather than air drying, the pressing stage alone can take upwards of 45–90 seconds to achieve the smooth, dense finish that makes it suitable for premium packaging.

Dry Press: In dry press molded pulp, the formed pulp structure needs time to air-dry or oven-dry so that moisture can fully evaporate. This drying buffer slows down the overall cycle time, especially for larger or thicker designs.

By contrast, plastic injection molding or cardboard die-cutting can often produce units in just a few seconds. However, molded pulp offers environmental advantages and custom shapes, which is why more brands are willing to accept slightly longer lead times in favour of sustainable impact.

How Thick Can Molded Pulp Be?

When designing molded pulp packaging, thickness plays a critical role in both durability and manufacturability. While there’s no one-size-fits-all due to the varying structural requirements and processing method, there are industry best practices and technical limitations. With wet press technology,

Wet Press: Wet-press molded pulp offers a more premium finish with a thinner profile. We are able to achieve a lower thickness at around 0.7mm, with most applications ranging from 0.7mm – 1mm.

Dry Press: Dry-press molded pulp is better suited for industrial or protective applications as it allows us to create thicker products. Standard thickness will typically range from 1.5 – 2mm, but by using corrugated fibres we are able to achieve up to 3mm max thickness for added durability and shock absorption.

⚠️ Pro Tip:

– Thinner pulp = faster production but lower strength and may tear easily.

– Thicker pulp = higher impact strength but longer cycle time and material cost.

Choosing the right thickness is all about balancing aesthetics, structural integrity, and production efficiency, our engineering team at Fenix Industries can assist you in choosing the right thickness for your products.

Other FAQs About Molded Pulp Packaging

What are the main design limitations for molded pulp packaging?

Molded pulp requires spacing between features and cavities (typically 8mm or more). Draft angles for paper pulp packaging can be as low as 5% but will depend on the height of the product.

What is the maximum height for molded pulp products?

The maximum height for molded pulp products will vary based on the manufacturer, but it is also dependent on the structural design. Fenix Industries suggests a maximum height of 15cm (5.9 inches) as a general rule of thumb.

Can I achieve consistent colour across molded pulp packaging?

There may be slight color variances across batches depending on your volume. Each batch of pulp is individually mixed in large vats and could result in minor differences generally not visible to the naked eye.

What colours can we produce for molded pulp?

There is generally no limitation for what colour you decide to use for molded pulp, however, colours may appear slightly faded and may not be able to achieve the exact sharpness. The colours we typically run are black and red.

What types of fibres can we use for molded pulp products?

The main fibres we use at Fenix Industries are bamboo and sugarcane (bagasse) and have been perfecting the combination over 20 years. There are other fibres available such as wood paper, hemp, recycled corrugated cardboard, or even newspaper depending on your needs.

Start Your Sustainable Packaging Journey with Fenix Industries

At Fenix Industries, we specialize in high-performance, eco-conscious molded pulp packaging. Whether you’re launching a new product or transitioning away from plastic, we help you design and deliver custom packaging solutions that stand out on shelves—and support your sustainability goals. Our team of packaging industry veterans are ready to help you take your brand to the next level in sustainability!

👉 Let’s work together. Contact us today to get started with a custom molded pulp solution.